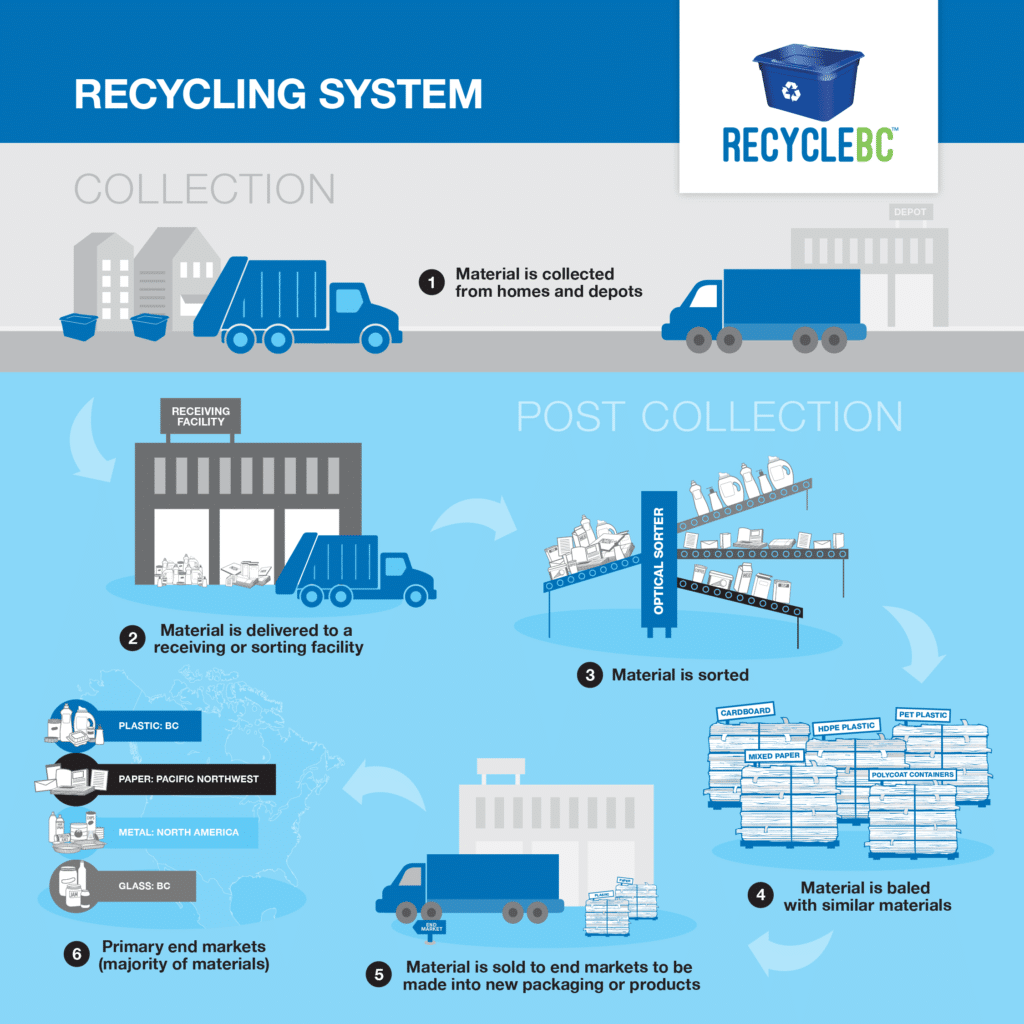

STEP FIVE

Converted into raw materials and recycled into new products

Once a full truck load of each sorted and baled material is ready, they are shipped off to end markets and processed into new raw materials. Many materials are pelletized or shredded but some are spun into fibre or crushed into fine particles. These raw material commodities are sold to manufacturers and turned into new products!

Many materials are recycled back to their original purpose, like plastic bottles and paper products – closing the loop of the product’s life cycle. Others are transformed into completely new products like furniture, car bumpers and shelving. Some materials, such as steel and aluminum cans, have no limit to the number of times they can be recycled back into new materials.

Recycling materials reduces the need to use virgin raw materials.